|

| Future Science-GIF |

6) Quantum Computers:

What Is Quantum Computing?

Moore’s Law (or the exponential growth of integrated circuits) is actually referring to the fifth paradigm of computation. Here’s the list of the underlying technologies: (1) Electromechanical; (2) Vacuum Tube; (3) Relay; (4) Transistors; and (5) Integrated Circuits.

Quantum computers may well be the sixth paradigm, given that they work in a fashion that is entirely different from “classical” computers.

A classical computer performs operations using classical “bits” — these “bits” can be in only one of two states: “0” or “1.”

In contrast, a quantum computer uses "quantum bits," or "qubits." Thanks to a principle called quantum superposition, these qubits can have a value of “0”, “1,” or both “0 AND 1” at the same time.

|

| The D-Wave 1,000 qubit processor. A 2000 qubit version will be available in 2017 |

This capability allows quantum computers to solve certain types of complex problems that are intractable for conventional computers. Frankly, really exciting problems for society today

The power of qubits is that they scale exponentially. A two-qubit machine allows you to do four calculations at once. A three-qubit machine can do eight calculations. A four-qubit machine gives you 16 calculations, all simultaneously.

|

| Developmental quantum computing systems |

By the time you get to 300 qubits, you’ve got a computer that can do more “calculations” than there are atoms in the universe.

That’s why the blog TechTarget described quantum computing this way: “Development of a quantum computer, if practical, would mark a leap forward in computing capability far greater than that from the abacus to a modern day supercomputer, with performance gains in the billion-fold realm and beyond.”

What Are the Implications of Quantum Computing?

|

| D-wave |

The implications of true quantum computing at scale are staggering, of extraordinary impact to society today (which is why I’m tracking it).

In my opinion, here are the top five applications:

Machine Learning: Much of machine learning is about “pattern recognition.” Algorithms crunch large datasets to find signals in the noise, and the goal is to maximize the number of comparisons you make between data to find the best models to describe that data. With quantum computing, we’ll be able to do this processing orders of magnitude more effectively than with classical computing. Quantum computing will allow you to compare much, much more data in parallel, simultaneously, and all permutations of that data, to discover the best patterns that describe it. This will lead to fundamentally more powerful forms of AI much more quickly than we expect. Expect quantum computing to cause a positive inflection point (upward) for the speed at which the world develops AI (which, by the way, is why Google is working so hard on it).

Medicine: Quantum computing will also allow us to model complex molecular interactions at an atomic level. This will be particularly important for medical research and drug discovery. Soon, we’ll be able to model all 20,000+ proteins encoded in the human genome and start to simulate their interactions with models of existing drugs or new drugs that haven’t been invented yet. Based on the analysis of these drug interactions, we’ll be able to find cures for previously incurable diseases and hopefully accelerate the time to market for new drugs. Using quantum computer simulations will be the way we design and choose our next generations of drugs and cancer cures.

Chemistry (and Climate Change): Worried about the climate crisis? Wondering what we can do about it? Quantum computers may be our newest tool to understand what is going on and to fight it. They will allow us to unlock “simulation-driven” solutions, perhaps design new catalysts that actually capture carbon from the atmosphere and turn it into new and valuable products at low cost and energy use.

Material Science & Engineering: Because we can simulate atomic interactions, we’ll explore and invent entirely new, better materials. We might find better superconductors, better magnets, materials that will allow us to create much higher energy density batteries, and so on. Since 2011, the U.S. federal government has granted over $250 million to the Materials Genome Initiative in an effort to “discover, manufacture, and deploy advanced materials twice as fast, at a fraction of the cost.”

Biomimetics, Energy Systems & Photovoltaics: Scientists believe that much of the world is built atop quantum systems. Processes like photosynthesis, for example, are likely dependent on quantum mechanical systems. Thus, as we look to the natural world for inspiration to build better energy systems or stronger materials, we’ll only fully realize their potential when we can model these processes with quantum computers. This will lead to many advances and discoveries across the board.

Bottom Line: When quantum computing pans out, we’ll be able to control the very building blocks of the universe.

|

| IBM_Quantum-Computer_Qubit |

Who’s Working on Quantum Computing?

There’s a race going on — a race to prove something called “quantum supremacy.”

Quantum supremacy is essentially the test that validates that the computer you have is, in fact, a quantum computer.

In the U.S., three major players are in the game right now:

IBM

Rigetti Computing, a startup out of Silicon Valley

(And perhaps a fourth — D-Wave Systems. They’ve developed chips with qubits, but these haven’t yet been conclusively proved to operate as a quantum computer.)

Both Rigetti Computing and Google believe they will reach “quantum supremacy” in the next 12 to 18 months.

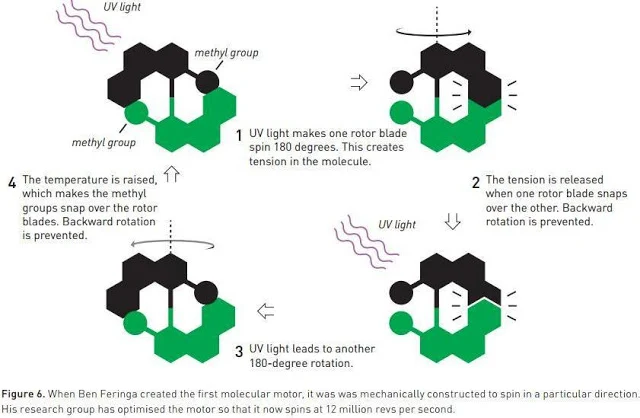

7) Nanomachines: The Nobel Prize in Chemistry 2016 was awarded jointly to Jean-Pierre Sauvage, Sir J. Fraser Stoddart and Bernard L. Feringa "for the design and synthesis of molecular machines".

They developed the world's smallest machines:

A tiny lift, artificial muscles and miniscule motors. The Nobel Prize in Chemistry 2016 is awarded to Jean-Pierre Sauvage, Sir J. Fraser Stoddart and Bernard L. Feringa for their design and production of molecular machines. They have developed molecules with controllable movements, which can perform a task when energy is added.

The first step towards a molecular machine was taken by Jean-Pierre Sauvage in 1983, when he succeeded in linking two ring-shaped molecules together to form a chain, called a catenane. Normally, molecules are joined by strong covalent bonds in which the atoms share electrons, but in the chain they were instead linked by a freer mechanical bond. For a machine to be able to perform a task it must consist of parts that can move relative to each other. The two interlocked rings fulfilled exactly this requirement.

The second step was taken by Fraser Stoddart in 1991, when he developed a rotaxane. He threaded a molecular ring onto a thin molecular axle and demonstrated that the ring was able to move along the axle. Among his developments based on rotaxanes are a molecular lift, a molecular muscle and a molecule-based computer chip.

Bernard Feringa was the first person to develop a molecular motor; in 1999 he got a molecular rotor blade to spin continually in the same direction. Using molecular motors, he has rotated a glass cylinder that is 10,000 times bigger than the motor and also designed a nanocar.

2016's Nobel Laureates in Chemistry have taken molecular systems out of equilibrium's stalemate and into energy-filled states in which their movements can be controlled. In terms of development, the molecular motor is at the same stage as the electric motor was in the 1830s, when scientists displayed various spinning cranks and wheels, unaware that they would lead to electric trains, washing machines, fans and food processors. Molecular machines will most likely be used in the development of things such as new materials, sensors and energy storage systems.

8) Making Of Artifitial Leaf to produce efficient and pollutionless energy from CO2, Sunlight and water:

A) Artificial Leaf Is 10 Times Better at Generating Hydrogen from Sunlight:

A "hydrogen economy" sounds just about as green and eco-friendly as it gets. Fuel cells that combine hydrogen with ambient oxygen in the air can generate electricity with naught but pure water as a byproduct—which is great if you hate pollution and are thirsty. The problem we face now is the source of our hydrogen: the vast majority of it comes from fossil fuels, specifically natural gas. And while transforming methane into hydrogen is 80 percent efficient, that other 20 percent is carbon dioxide.

The vast majority of the accessible clean hydrogen on Earth is locked up with oxygen in water, but breaking apart H2O into an O and a useful H or two isn't a particularly environmentally-friendly or efficient process to get involved in. The fantasy is an "artificial leaf," a passive, inexpensive thing that you can stick in water and expose to sunlight, then watch as it bubbles off all the hydrogen and oxygen you need. People have been working on these, but Caltech has just made an enormous amount of progress with an artificial leaf that, according to the researchers, "shatters all of the combined safety, performance, and stability records for artificial leaf technology by factors of 5 to 10 or more."

Caltech's Joint Center for Artificial Photosynthesis has been working on ways of turning sunlight, water, and CO2 into useful chemical fuels for the last half decade. They've just published a paper in Energy and Environmental Science describing a new design that's efficient, simple, relatively inexpensive, and reliable enough to suggest a path towards industrialization.

The Caltech design uses two electrodes (a photoanode and a photocathode) separated by a membrane. The photoanode is made of gallium arsenide, which is an excellent light absorber, but tends to oxidize when exposed to water. A layer of titanium dioxide helps keep the photoanode stable and protected, and a layer of nickel on top of that acts as a catalyst. When exposed to sunlight, the photoanode oxidizes water molecules, generating oxygen (O2) as well as protons and electrons, which pass through the membrane and are recombined by the photocathode into hydrogen (H2). Put all of this together, and you end up with a single, fully integrated system that cracks water into oxygen and hydrogen when you put it in the sun:

The current incarnation of the device isn't completely stable. In other words, there is some degradation, such that you couldn't leave it running indefinitely. The initial solar-to-hydrogen conversion efficiency was almost 11 percent, decreasing to 10 percent after 40 hours of operation, and 9 percent after a total of 80 hours of operation. Eventually (although the paper doesn't say exactly when) the device experienced "catastrophic failure;" it's left up to us to imagine exactly what that meant. The source of this failure seems to be defects in the protective titanium oxide film originally caused by dust particles on the semiconductor surface when the film was being deposited. The electrolyte was able to sneak in through these defects, slowly eating away at the TiO2 and resulting in a linear decrease in conversion efficiency to the point of failure.

The good news is that the researchers have identified the cause of the degradation, and they're pretty sure that it's a solvable issue. They suggest that it might be possible to use sacrificial arrays of nanowires to electrochemically isolate the defects, allowing the device to function longer, and results for such systems will be reported as soon as they've gotten them to work. We hope they’ll do it soon, because being able to turn sunlight directly into hydrogen efficiently on a residential scale could abruptly make a hydrogen economy much more realistic.

B) RCA graduate develops an artificial leaf that’s capable of producing oxygen:

|

| silk-leaf |

Human beings have long since been looking up at space, wondering when mankind will finally be technologically-advanced enough to colonize space. While staring heavenwards recently, we stumbled across this jaw-dropping development by RCA graduate Julian Melchiorri. A synthetically developed leaf, this concept called the Silk Leaf Project, is capable of absorbing water and carbon dioxide to produce oxygen, just the way a real plant does! Quoting Melchiorri, “NASA is researching different ways to produce oxygen for long-distance space journeys to let us live in space. This material could allow us t0 explore space much further than we can now.”

The Silk Leaf Project was developed as part of the Royal College of Art’s Innovation Design Engineering course in collaboration with Tufts University silk lab. Made from chloroplasts suspended in a matrix made out of silk protein, the leaf “as an amazing property of stabilizing molecules.” Not unlike real plants, these leaves created by Melchiorri also require light and a small amount of water to produce oxygen. This is the first man-made biological leaf in the history of mankind and an idea as such could help us step beyond boundaries, in terms of technology and lifestyle. Melchiorri sure deserves a pat on his back for his brilliance!

9) 3D printing technology will revolutionize Manufacturing and Medical Industry:-

3D printing, also known as additive manufacturing (AM), refers to processes used to synthesize a three-dimensional object in which successive layers of material are formed under computer control to create an object. Objects can be of almost any shape or geometry and are produced using digital model data from a 3D model or another electronic data source such as an Additive Manufacturing File (AMF) file.

Futurologist Jeremy Rifkin claimed that 3D printing or AM signals the beginning of a third industrial revolution, succeeding the production line assembly that dominated manufacturing starting in the late 19th century.

The term 3D printing's origin sense is in reference to a process that deposits a binder material onto a powder bed with inkjet printer heads layer by layer. More recently, the term is being used in popular vernacular to encompass a wider variety of additive manufacturing techniques. United States and global Technical standards use the official term additive manufacturing for this broader sense. ISO/ASTM52900-15 defines seven categories of AM processes within its meaning: Binder Jetting, Directed Energy Deposition, Material Extrusion, Material Jetting, Powder Bed Fusion, Sheet Lamination and Vat Photopolymerization.

3D modeling

3D printable models may be created with a computer-aided design (CAD) package, via a 3D scanner, or by a plain digital camera and photogrammetry software. 3D printed models created with CAD result in reduced errors and can be corrected before printing, allowing verification in the design of the object before it is printed.

Printing:

Before printing a 3D model from an STL file, it must first be examined for errors. Most CAD applications produce errors in output STL files: holes, faces normals, self-intersections, noise shells or manifold errors.A step in the STL generation known as "repair" fixes such problems in the original model. Generally STLs that have been produced from a model obtained through 3D scanning often have more of these errors. This is due to how 3D scanning works-as it is often by point to point acquisition, reconstruction will include errors in most cases.

Finishing

Though the printer-produced resolution is sufficient for many applications, printing a slightly oversized version of the desired object in standard resolution and then removing material[35] with a higher-resolution subtractive process can achieve greater precision.Some printable polymers such as ABS, allow the surface finish to be smoothed and improved using chemical vapor processes based on acetone or similar solvents.

Some additive manufacturing techniques are capable of using multiple materials in the course of constructing parts. These techniques are able to print in multiple colors and color combinations simultaneously, and would not necessarily require painting.

Some printing techniques require internal supports to be built for overhanging features during construction. These supports must be mechanically removed or dissolved upon completion of the print.

Processes

Several 3D printing processes have been invented since the late 1970s.The printers were originally large, expensive, and highly limited in what they could produce.

A large number of additive processes are now available. The main differences between processes are in the way layers are deposited to create parts and in the materials that are used. Some methods melt or soften the material to produce the layers, for example. selective laser melting (SLM) or direct metal laser sintering (DMLS), selective laser sintering (SLS), fused deposition modeling (FDM),[40] or fused filament fabrication (FFF), while others cure liquid materials using different sophisticated technologies, such as stereolithography (SLA). With laminated object manufacturing (LOM), thin layers are cut to shape and joined together (e.g., paper, polymer, metal). Each method has its own advantages and drawbacks, which is why some companies offer a choice of powder and polymer for the material used to build the object. Others sometimes use standard, off-the-shelf business paper as the build material to produce a durable prototype. The main considerations in choosing a machine are generally speed, costs of the 3D printer, of the printed prototype, choice and cost of the materials, and color capabilities

Large 3D printers

Large 3D printers have been developed for industrial, education, and demonstrative uses. A large delta-style 3D printer was built in 2014 by SeeMeCNC. The printer is capable of making an object with diameter of up to 4 feet (1.2 m) and up to 10 feet (3.0 m) in height. It also uses plastic pellets as the raw material instead of the typical plastic filaments used in other 3D printers.

|

| Large 3D printers |

Another type of large printer is Big Area Additive Manufacturing (BAAM). The goal is to develop printers that can produce a large object in high speed. A BAAM machine of Cincinnati Incorporated can produce an object at the speeds 200-500 times faster than typical 3D printers available in 2014. Another BAAM machine is being developed by Lockheed Martin with an aim to print long objects of up to 100 feet (30 m) to be used in aerospace industries

Microscale and nanoscale 3D printing

Microelectronic device fabrication methods can be employed to perform the 3D printing of nanoscale-size objects. Such printed objects are typically grown on a solid substrate, e.g. silicon wafer, to which they adhere after printing as they are too small and fragile to be manipulated post-construction.

In one technique, 3D nanostructures can be printed by physically moving a dynamic stencil mask during the material deposition process, somewhat analogous to the extrusion method of traditional 3D printers. Programmable-height nanostructures with resolutions as small as 10 nm have been produced in this fashion, by metallic physical vapor deposition through a piezo-actuator controlled stencil mask having a milled nanopore in a silicon nitride membrane.

Another method enhances the photopolymerization process on a much smaller scale, using finely-focused lasers controlled by adjustable mirrors. This method has produced objects with feature resolutions of 100 nm

Industrial applications:

Apparel

3D printing has entered the world of clothing with fashion designers experimenting with 3D-printed bikinis, shoes, and dresses.[ In commercial production Nike is using 3D printing to prototype and manufacture the 2012 Vapor Laser Talon football shoe for players of American football, and New Balance is 3D manufacturing custom-fit shoes for athletes

Automotive industry

In early 2014, the Swedish supercar manufacturer, Koenigsegg, announced the One:1, a supercar that utilizes many components that were 3D printed. In the limited run of vehicles Koenigsegg produces, the One:1 has side-mirror internals, air ducts, titanium exhaust components, and complete turbocharger assemblies that were 3D printed as part of the manufacturing process

Construction

The use of 3D printing to produce scale models within architecture and construction has steadily increased in popularity as the cost of 3D printers has reduced. This has enabled faster turn around of such scale models and allowed a steady increase in the speed of production and the complexity of the objects being produced.

Firearms

In 2012, the US-based group Defense Distributed disclosed plans to "[design] a working plastic gun that could be downloaded and reproduced by anybody with a 3D printer. Defense Distributed has also designed a 3D printable AR-15 type rifle lower receiver (capable of lasting more than 650 rounds) and a 30-round M16 magazine The AR-15 has multiple receivers (both an upper and lower receiver), but the legally controlled part is the one that is serialized (the lower, in the AR-15's case). Soon after Defense Distributed succeeded in designing the first working blueprint to produce a plastic gun with a 3D printer in May 2013, the United States Department of State demanded that they remove the instructions from their website.After Defense Distributed released their plans, questions were raised regarding the effects that 3D printing and widespread consumer-level CNC machining[ may have on gun control effectiveness

Medical devices

In October 24, 2014, a five-year-old girl born without fully formed fingers on her left hand became the first child in the UK to have a prosthetic hand made with 3D printing technology. Her hand was designed by US-based E-nable, an open source design organisation which uses a network of volunteers to design and make prosthetics mainly for children. The prosthetic hand was based on a plaster cast made by her parents.[163] A boy named Alex was also born with a missing arm from just above the elbow. The team was able to use 3D printing to upload an e-NABLE Myoelectric arm that runs off of servos and batteries that are actuated by the electromyography muscle. With the use of 3D printers, E-NABLE has so far distributed more than 400 plastic hands to children.

Bio-printing

As of 2012, 3D bio-printing technology has been studied by biotechnology firms and academia for possible use in tissue engineering applications in which organs and body parts are built using inkjet techniques. In this process, layers of living cells are deposited onto a gel medium or sugar matrix and slowly built up to form three-dimensional structures including vascular systems.The first production system for 3D tissue printing was delivered in 2009, based on NovoGen bioprinting technology. Several terms have been used to refer to this field of research: organ printing, bio-printing, body part printing, and computer-aided tissue engineering, among others.The possibility of using 3D tissue printing to create soft tissue architectures for reconstructive surgery is also being explored

Computers and robots

3D printing can also be used to make laptops and other computers and cases. For example, Novena and VIA OpenBook standard laptop cases. I.e. a Novena motherboard can be bought and be used in a printed VIA OpenBook case.

|

| 3&DBot holonomic robotic 3d printer from Brazil |

|

| 3D-printed robot MARC to be showcased at UK engineering event |

Open-source robots are built using 3D printers. Double Robotics grant access to their technology (an open SDK).On the other hand, 3&DBot is an Arduino 3D printer-robot with wheels and ODOI is a 3D printed humanoid robot

Art

In 2005, academic journals had begun to report on the possible artistic applications of 3D printing technology,[196] being used by artists such as Martin John Callanan at The Bartlett school of architecture. By 2007 the mass media followed with an article in the Wall Street Journal and Time Magazine, listing a 3D printed design among their 100 most influential designs of the year.[198] During the 2011 London Design Festival, an installation, curated by Murray Moss and focused on 3D Printing, was held in the Victoria and Albert Museum (the V&A). The installation was called Industrial Revolution 2.0: How the Material World will Newly Materialize

|

| Asian Art |

|

| Asian Art |

|

| GIAN PABLO VILLAMIL watches his MakerBot print a miniature of Nandi, Shiva's mount. |

|

| Ritual vessel in the shape of a rhinoceros, Chinese, late 1100s to 1050 BCE, with 3D-printed replica |

|

| Seated Ganesha, an Indian sculpture from the 13th century, captured and reprinted in translucent plastic. |

High School students from Wyomissing Area Jr/Sr High School in Pennsylvania, United States present their use of 3D Printing in the classroom3D printing, and open source 3D printers in particular, are the latest technology making inroads into the classroom. 3D printing allows students to create prototypes of items without the use of expensive tooling required in subtractive methods. Students design and produce actual models they can hold. The classroom environment allows students to learn and employ new applications for 3D printing.RepRaps, for example, have already been used for an educational mobile robotics platform

End Notes:

Science have no boundaries and its consequence and effects are endless, each and every passing day the new discovery and technology popping up with our utter surprises. therefore I cannot say that these above mentioned discoveries are ultimate and final but there are many more and continue to grow day by day.

This article is written on the basis of my strict personal observations , I will be pleased if readers share their valuable comment and give any suggestions if required. thank you.

Online Movies

Online Movies

No comments:

Post a Comment